High-speed train between Tangier and Casablanca tests started

1 Feb 2016

The national railways (ONCF) announced on January 19 that it would open the “dynamic testing” of the first Moroccan high speed train. Tests spread over several months and take place on the traditional line between Tangiers and Casablanca. The TGV is equipped with a laboratory where the railway experts and civil authorities consult with measurements taken by the onboard instruments. This train was received last June in Tangier, where it was subject since that time to static testing in the maintenance workshop inaugurated in September 2015, by H.M King Mohammed VI and the French president François Hollande. While the work of the TGV linking Casablanca to Tanger is progressing, the Moroccan Railways (ONCF) has already started thinking about the south extension of the high speed line from Casablanca to Agadir, which implies the realization of a new non-existent section between Marrakech and Agadir, according to the Morocco newspaper “Aujourd’hui”. ONCF has already launched preliminary studies to assess the feasibility and economic viability of the new segment. The ONCF conducted a first field study and passengers survey.Today, a Casa-Agadir travel by highway requires almost 5 hours at a cost approximately 60 USD, including toll costs. For those who choose the ONCF, namely a train then a bus between Marrakech and Agadir, the ride costs around 18 USD in first class, but requires 9 hours. Air is obviously the fastest but it is also the most expensive: the trip only lasts 3 hours in all but costs at least 80 USD (departing from Casablanca). The success of a new high speed line between Casablanca and Agadir assumes that its price is more attractive compared to the aircraft for a same duration of trip. The difficulty for ONCF will therefore be to find a balance between the need to offer attractive prices and the profitability of an infrastructure that will cost at least 2 to 2.5 billion USD. During a parliamentary session, the Minister of Transport said that the work of the high speed line connecting Tangier to Casablanca are finalized at 70% for a service in 2018. And to add that the Morocco ranked in first place at the African and Arab level in terms of railway infrastructure and the 55th row at the global level. To be noted that one viaduct of this Moroccan high speed line, called viaduct “El Hachef”, will be after completion the world’s largest train viaduct, said Mohamed Rabie Khlie, ONCF CeO. This viaduct extends over 3.5 km between Asillah and Tangier, North of the Morocco. The high-speed line connecting Casablanca, Tangier, is also the largest high-speed railway project in Africa

Source: http://menarailpost.com - Photo: by Rami75013 – Wikimedia Commons

Major infrastructure project to improve safety and frequency of freight and passenger traffic between Ukraine and EU

1 Feb 2016

Ukraine is moving an important step closer to Europe with the completion of the tunnel tube for a new transport connection under the Carpathian Mountains in the south-west of the country. The so-called Beskyd tunnel is being built by the Ukrainian construction firm Interbudmotazh and financed by a US$ 40 million loan provided by the European Bank for Reconstruction and Development (EBRD) and a parallel loan worth €55 million from the European Investment Bank (EIB). The new double-track tunnel is set to replace the old single-track one, which was commissioned exactly 130 years ago, when the region was part of the Austro-Hungarian Empire. The new tunnel will remove a major bottleneck in the European transport corridor V that links Ukraine with The European Union, by almost quadrupling capacity from the current 12 trains per day to 46 trains on completion of the tunnel.

The structure will be seismically stable and 1,765 metres long, 10.5 metres high and 8.5 metres high. The construction will require 130,000 tonnes of concrete and 8,000 tonnes of steel. The tunnel is expected to be fully operational by the end of 2017 or early 2018 and significantly reduce journey times between Lviv (in Western Ukraine) and Chop (near the borders of Hungary and the Slovak Republic). Sevki Acuner, EBRD Director for Ukraine, said: “This is a very important project for Ukraine and Europe. Modern transport links will boost cross-border trade and cooperation, and bring people and businesses closer together. Better access will also allow the region to realize its potential as a destination for tourism and investment”. Corridor V is one of the ten Pan-European transport corridors, defined in Crete in 1994; it runs from Venice and Trieste (Italy) v ia Ljubljana (Slovenia) and Budapest (Hungary) to Lviv (Ukraine). The Beskyd tunnel is the first railway infrastructure project in Ukraine to which the contractual framework standards of the INternational Federation of Consulting Engineers (FIDIC – Fédération Internationale Des Ingénieurs-Conseils) as well as the procurement policies of the EBRD were applied. It has become an important industry benchmark for transparency and efficiency. The EBRD is the largest international financial investor in Ukraine. As of 1 January 2016, the Bank had a total cumulative commitment of approximately €12 billion in 355 projects throughout the country. Last year alone the EBRD signed 30 transactions in the country for €1 billion.

Source: http://www.ebrd.com/news - Photo: ©EBRD/Anton Usov

Mayor of Istanbul welcomed address at SmartRail Eurasia

1 Feb 2016

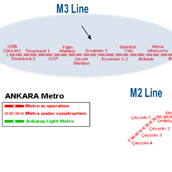

Dr. Kadir Topbaş ,the Mayor of Istanbul Metropolitan Municipality, welcomed address at SmartRail & Metro Eurasia, that took place last 26-27th January in Istanbul. He officially opened the landmark two day event. A trained architect and strong supporter of public transport, Dr. Topbaş, welcomed delegates attending the event from across the region and explored plans for the development of the city’s growing transport networks. With rail and metro in Eurasia undergoing a rapid period of modernization, signalling, telecommunications, rolling stock and IT technology are all the subject of significant investment. Turkey alone will be allocating $46 billion to rail and metro investment by 2023. And in response to this growth, SmartRail Eurasia will bring together the leading organizations and individuals shaping the rapid development of public transport in the region. Alex Williamson, Manging Director of Global Transport Forum, the organizer of SmartRail Eurasia stated; “We were honoured to welcome Dr. Topbaş as a speaker and his presence showed the importance of public transport development within the region, and the focus which Eurasia’s leaders place upon it. It was a fascinating, engaging and important event in the industry calendar”. Dr. Kadir Topbaş joined fellow high-level speakers including Fatih Turan (General Manager, AYGM, Ministry of Transport), Sönmez Alev (General Manager, Izmir Metro), Necmettin Tahiroglu, (General Manager, Ankara Metro, EGO), Halil Korkmaz (General Manager TCDD Region 1), Renata Susa (President of Management Board, Croatia Railways), Libor Lochman (Executive Director, CER), Asghar Bahramali (Project Director, Iran Railways) and many more. SmartRail and Metro Eurasia took place in Istanbul, Turkey on 26-27th January at the Radisson Blu Şişli hotel. This event was a unique business and development platform covering the entire value chain within Eurasia’s leading authorities, rail and metro operators, international contractors and solutions providers.

Photo: by Ex13 Wikimedia Commons

Ansaldo STS Awarded LA West Side Extension

1 Feb 2016

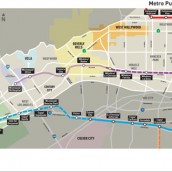

Ansaldo STS awarded 31.5 million USD contract for new Signalling and Train Control system for LACMTA Ansaldo STS (ASTS) – on December 31st 2015 – was awarded a 31.5 million USD contract to design, furnish, test and commission a Signalling and Train Control (S&TC) system for the Los Angeles County Metropolitan Transportation Authority (LACMTA) West Side Subway Extension. The extension will be approximately 3.9 miles from its current terminus at Wilshire/Western Station to a new Wilshire/La Cienega station and will include a total of 3 new stations. The new system will be designed to ensure the safe and efficient movement of trains along the extensions’ mainline and interlocked tracks. This system will meet these requirements through the implementation of Automatic Train Protection (ATP) functions and support of Automatic Train Operation (ATO) and Automatic Train Supervision (ATS) functions. The new system will also employ Train-To Wayside Communications (TWC). Stefano Siragusa, CEO of Ansaldo STS said: “This contract win exemplifies furthermore Ansaldo STS’s competitive position in the US market and highlights the company’s commitment to delivering quality leading edge products and services to its customers”. Ansaldo STS is a leader in the global rail market, with over a century of experience in developing and supplying leading edge technologies in the Americas, Australia, and around the world.

Wegh Group acquires the OLMI Sleeper Technology line of business to complete their technological offer for the railway industry

1 Feb 2016

In line with the expansion strategy to widen their product portfolio, Wegh Group acquires OLMI Sleeper Technology line of business from Alfa Laval Olmi.

Wegh Group, announce today the acquisition of OLMI Sleeper Technology line of business from Alfa Laval OLMI expanding their total Know-how thus positioning on the market as the major global leading provider of solutions for the manufacturing of the railway concrete sleepers and turnout bearers.

OLMI Sleeper Technology and SICI represent two excellences in the field: the first one in the Carousel process and the second one in the Long-Line process. Thanks to the synergy of these two historical brands, WEGH Group S.p.A. acquires an international leadership with 97 plants installed and referenced in different environmental and social sectors, such as, Italy, Russia, Mozambico, Germany, Cuba, Spain, Brazil, Saudi Arabia, Uzbekistan, Abu Dhabi, Argentina, Poland, Perù, Iran, Malaysia, India, Boliva, etc.

The acquisition of Olmi Sleeper Technology and the consolidated technology from SICI, complete Wegh experience and expertise as manufacturer of railway sleepers to grant our customers a continuous product and process improvement as well as to assure a dedicated assistance both in terms of quality and quantity of sleepers as well as in terms of expected return of investments.

The high speed line between Jakarta and Bandung has started

1 Feb 2016

President of Indonesia Joko Widowo was joined by Jakarta Governor Basuki Purnama on January 21to lay a ceremonial foundation stone in Cikalong Witan to mark the launch of construction of a 142 km high speed line between Jakarta and Bandung. Indonesian officials had agreed last October to proceed with a “business to business” agreement whereby a consortium with 40% Chinese involvement would develop the railway with no financial involvement from the government in Jakarta. Three-quarters of the estimated US$5·5bn cost is coming via loans from China Development Bank, with China Railway International Co Ltd holding a 40% share in the construction consortium. Domestic participants include construction firm Wijaya Karya, toll road operator Jasa Marga and national railway PT KAI. Subject to completion of the land acquisition process, construction of the railway is expected to take three years, with trains planned to start running in the first half of 2019. The current plans would see terminus stations built on the edges of both cities at Jakarta Halim and Bandung Tegalluar, with metro and light rail links to both envisaged under existing urban rail plans. Two intermediate stations are to be built at Karawang and Walini. Trains would run at up to 250 km/h, giving an end-to-end journey time of between 40 min and 60 min. Wijaya Karya has appointed a consortium of engineering consultancy Atkins, architects Aedas and Singapore-based developer Surbana Jurong to design commercial and residential property around the stations as part of a development initiative planned to last until 2030.

Key Points

• The Jakarta-Bandung railway will become Indonesia’s first ever high-speed line; • Critics consider the project an odd choice as existing infrastructure between both cities is relatively adequate (railway and roads) while the route is not that critically important for business; • Indonesia is plagued by inadequate infrastructure (both in quality and quantity) causing high logistics costs while making the country’s investment climate less attractive. It also causes social issues as it limits people’s access to healthcare; • Two listed state-controlled companies are involved in the project: Jasa Marga and Wijava Karva.

Sources: http://www.railwaygazette.com – http://www.indonesia-investments.com - Photo: by Gunawan Kartapranata – Wikimedia Commons

Asia’s largest underground railway station opens for business

1 Feb 2016

Second in the world only to New York’s Grand Central Terminal, Asia’s largest underground railway station, Futian, is now fully operational. Situated in downtown Shenzhen, Guangdong Province, China, the giant complex covers a total area of 147,000 square meters, or about the size of 21 football fields. The opening of Futian, is another landmark in the completion of the Guangzhou-Shenzen-Hong Kong Express Rail Link. The first phase, Shenzen (North) – Guangzhou (South) , commenced revenue operation in December 2011. Now Futian is online, the final phase, connecting Shenzhen-Futian to Hong Kong (Kowloon), is under construction and planned to be completed by third quarter of 2018. According to reports in Hong Kong newspaper, Wen Wei Po, the station cost RMB3.95 billion (HK$4.72 billion). Tickets from Futian to Guangzhou South sell for RMB82 (HK$98) and RMB108 (HK$129) for second class and first class cabins, respectively. The station’s three underground floors will have seating for excess of 3,000 passengers and will be operated by Guangzhou Railway Corporation. The estimated journey time after the construction of corridor will be reduced to 14 minutes between West Kowloon Terminus and the newly opened Futian station, 23 minutes between Hong Kong and Shenzhen North and 48 minutes between Hong Kong and Guangzhou South. According to the new train timetable, there will be 12 pairs of high-speed trains between the Futian Station and Guangzhou South Station running each day.The mainland China section of the high-speed railway is largely complete, but the line connecting into Hong Kong has suffered delays as the total cost of the project has continued to spiral. According to reports in the Hong King Free Press, the total construction cost has risen to HK$85.3 billion, which is 19 percent greater than the last estimate of HK$71.5 billion in 2014 and 31 percent more than the original estimate of HK$65 billion in 2010. There has also been a debate over the presence of Chinese customs officials, carrying out their duties within the special administrative region of Hong Kong. The recently departed MTR Corp Ltd chairman Raymond Ch’ien Kuo-fung stated that “99 per cent” of the delay and extra cost of the Guangzhou-Shenzhen-Hong Kong high-speed rail link were due to “objective environmental reasons.” The MTRCL had previously blamed the delay on complicated conditions at West Kowloon and the geology at the cross-border area beneath a protected wetland. The opening of Futian, Asia’s largest underground railway station is though a major sign that the line is close to completion.

Source: http://www.smartrailworld.com/ - Photo: By 颐园新居 – Wikimedia Commons

250 new metro trains for the London Underground

1 Feb 2016

London Underground has invited Alstom, Bombardier, CAF, Hitachi and Siemens, which previously pre-qualified, to submit tenders to supply a fleet of 250 trains under its New Tube for London project. A concept design for the new trains was completed in 2014 by Transport for London and design specialist Priestman Goode. The trains will be the first on the deep-level Tube lines, which have a very restricted loading-gauge, to have air cooling. They will have walk-though coaches and wider doors than existing trains. London Underground wants bidders to submit their proposals this summer, and plans to award a contract in autumn 2017 so that the new trains can enter service in the early 2020s. The trains will be deployed on four lines: with 100 trains each for the Piccadilly and Central lines, 40 for the Bakerloo Line, and 10 for the Waterloo & City Line. Introduction of the new fleet together with modernized signalling will increase capacity on the Piccadilly Line by 60% or 21,000 passengers/h, by 35% or 7000 passengers/h on the Waterloo & City Line, and by 25% on the Bakerloo (9000 passengers/h) and Central (12,000 passengers/h) lines.

Source: http://www.railjournal.com

Photo: Transport for London

When tickets become smart

1 Feb 2016

We try to give a general vision of the evolution of ticketing from the past through the present and towards the future. Mrs. Montserrat Palasì, Indra’s director of Transports in Europe, helped us in this short but deep analysis

In this short but deep market analysis, Railway Engineering tries to detect the evolution of “ticketing”. To be more precise we see how people bought travel tickets (both in the public and private transport) in the past and which are the most used modern technologies today. Thanks to the help of an expert: Mr. Montserrat Palasì, *Indra’s director of Transports in Europe we give a look of the evolution of the market.

Mrs. Montserrat Palasí, could you please describe us in short the evolution of “ticketing” from the past to the present?

The evolution of the ticketing depends on the point of view of the operator, due to the needs of the transportation in every country/city at a time, and it is closely linked to the natural need of promoting the use of public transport, while making it cost-effective and sustainable. It was first based on manual collection through simple paper tickets, then moved to automatic fare collection with magnetic stripe tickets, featuring longer durability and higher data capacity to support a wider range of transportation services, and nowadays it is resolving around the use of secure higher speed and data capacity contactless smartcards in an interoperable and intermodal environment.

And what about the future of ticketing?

Telecommunications technologies have become one of the most evolving areas of knowledge during the last few decades. Internet and mobile applications have revealed to be both source of a stunning new world of services and commercial possibilities, and a definitive partner to enhance the productivity of companies and entities of all kinds. The transportation sector has not remained oblivious to such changing environment, and is definitively giving the steps towards that clouded and multi-service challenge through complementing, when not just replacing, the current card-centric approach based on the core ticketing logic being stored inside the contactless smartcards or magnetic stripes. With a back-office-centric approach, travel media as smartcards are just account-registered identifiers, and all the business logic to provide seamless door-to-door interoperable and intermodal services resides at the back-office level, drastically reducing front-end equipment procurement, maintenance, and operation costs, while exponentially bursting the business possibilities once the chains of the field hardware limitations are broken. NFC-enabled devices as unique point of service to customers and cell phone payment application with NFC, the use of financial cards as travel tokens, or the implementation of account-based systems, are just a few examples of paradigms that are paving the way for the ticketing sector to reach the future. Other trends are the importance of the intermodality systems for the smart mobility solutions, that allow the combined use of mixed modes of transport; the operator clearing house, etc.

Which means can the Transport Companies use today in order to offer to the consumer a fast, convenience and functional way to buy a ticket?

It is very important for the Transport Companies to offer a way to buy tickets that is secure to avoid fraud, that is fast to increase the volume, that is less expensive to reduce the final price and that is reliable to increase the satisfaction. The application of technology to public transport management improves the service and, the most important, fosters its use.The traditional ticket vending machines or sales ticket offices are still in place, and will be for long time, but mobile-based applications powered with shopping applications connected to the ticketing back-offices are starting to sparkle the transportation systems, and will become essential to access the travel services in the near future.

How is the ticketing market developing in the metro, tram and rail-ways? Are there differences among ticketing in the local, national and international transports?

The systems that these ways of transportation use are very similar in the purpose. The final system implemented depends on the operational and pricing rules they have to follow. Although with plenty of exceptions, the most massive the transportation network is, the sooner it embraces new technologies to achieve its goals in terms of higher revenues, more cost-effective operation, etc. But both the fact that in general technology is becoming cheaper, and the search for interoperability and intermodality offering seamless door-to-door travel products, are making metro, tram, suburban, and bus transit networks to go the same path. Moreover when it comes to talk about the ticketing market development on transportation, it currently makes a difference in favor of short distance transit networks, featuring far more evolved ticketing systems where higher transaction speeds, better cost-effectiveness, and richer business rules, are of the essence. But the already mentioned search for seamless door-to-door services comprising local, national, or international different modes, even those that are not particular to the ticketing sector as tolling systems, is starting to promote the integration of both worlds, short and long distance transportation networks, and will hopefully bring a full and homogeneous transportation ecosystem in the long term.

Which are the most developed Countries in this field? Which are the most advanced Transport Companies in the ticketing offer from a technological, functional and fastness point of view?

Nowadays USA is maybe the most demanding country of ticketing systems based on new mobile technologies, while European countries are mainly focused on knocking down barriers by building up interoperable and intermodal systems. Probably, the Transport Companies of USA and UK are some of the most advanced ones.

Which are the main novelties in this field? Nowadays, the use of the NFC technology and the financial cards are the most requested, but it is true that there are cities with both technologies already implemented.

Mobile ticketing applications, and financial cards used as travel tokens, are two of the most demanded new breaking technologies. Migration from a card-centric to a back-office-centric approach is already in place, and seems to have a brilliant future ahead.

Do you think that the old booking offices will disappear? How do you think the elder travelers could do without the booking office?

Disappearing is maybe an extreme statement, but nowadays there are many transportation companies that are really doing their best to replace those offices by automatic ticket vending machines, and the exponential evolution of mobile ticketing applications in the future will make them to be on the brink of extinction. A main trend of ticketing systems is making life easier to travelers, and elder ones will be able to get used to the new environment pretty straight forward.

by Anna Celenta – Photo by Indra

First Metropolis trainset delivered for Kochi Metro Rail

1 Feb 2016

Alstom has delivered last January 2, 2016, ahead of schedule, the first Metropolis trainset to Kochi Metro Rail (KMRL) of the 25 trainsets ordered by Delhi Metro Rail Corporation (DMRC) in August 2014. An official ceremony was held on this occasion at the Alstom’s Sricity facility where the metro was built. Present at the ceremony were Shri. Venkaiah Naidu, Union Minister for Urban Development, Parliamentary Affairs, Housing and Urban Poverty Alleviation; Shri Aryadan Muhammed, Minister for Power & Railways, Kerala; Elias George, Managing Director of KMRL; Mangu Singh, Managing Director of DMRC; Jean Francois Beaudoin, Deputy Senior Vice President, Alstom, Asia Pacific and Bharat Salhotra, Managing Director of Alstom India. This is the first time that a Metropolis trainset was produced at the Sricity facility in India. The 25 trainsets will circulate on an elevated metro rail network that is 25 km long and includes 22 stations. The line is expected to open in June 2016. The unique design of the Kochi metro, unveiled in September 2015, has set a new benchmark in urban mobility in India. The front end features LED lights that are in the shape of elephant’s tusks. As the metro will run on a viaduct, it will lighten the city at night.Speaking on the occasion, Elias George, Managing Director of KMRL said, “It is a big achievement for Kochi metro. These metro cars are manufactured end-to-end by Alstom in India and are delivered ahead of schedule at a record time of 15 months. I would like to take this opportunity to congratulate the teams from Alstom, DMRC and KMRL, who worked hard to make it happen.” “The delivery of the first train set of Kochi metro marks another major milestone for Alstom in India. The project re-affirms our strong commitment and endorsement of the ‘make in India’ initiative of current government. Kochi metro is our second metro contract in the country after Chennai, and with the recent award of the Lucknow contract, we are well geared to serve India. We are proud to be able to contribute to the metro development of the country”. Bharat Salhotra commented. With about 5,000 Metropolis cars sold to over 20 cities, Alstom is one of the largest metro suppliers in the world. Designed to address the specific needs of each city, Metropolis offers a large range of options and configurations, a high level of passenger comfort and innovative features to optimize energy consumption and life cycle costs.

Global experts gather to deliver a vision of the metro network of the future

26 Nov 2015

The rapidly evolving business of delivering metro networks to global cities was the big focus of the 6th annual SmartMetro event, held in Copenhagen from 3rd to the 5th November 2015. The three day event presented hours of expert insight, practical case studies, high-level discussion, interactive workshops and networking for the 250+ delegation that came to Copenhagen from 5 continents. Co-located with the 6th annual CBTC World Congress, the showcase covered topics such as technology integration, passenger management and sustainability while discussing how to place Communications Based Train Control (CBTC) at the heart of smart operation upgrades to improve performance. With our increasingly inter-connected and urbanized world, evolving IT and the digital revolution that give metro systems an opportunity to improve service and meet ever evolving passenger demands were a big focus for the global speakers assembled in the Danish capital. Having focussed on CBTC for the past five editions, this year, the show evolved into the SmartMetro Congress to include all these exciting new areas and more. Global Transport Forum was honoured to have the support of local transport agencies Metroselskabet and Banedanmark who hosted popular site visits for the delegation. Further information and a deep analysis of the speech of the forum on the issue of Railway Engineering.

(Photo: – Copenhagen Metro by Stig Nygaard Copenhagen, Denmark http://www.rockland.dk – trough Wikimedia Commons)

Smartrail Usa: the next generation of technology for national transit operators

26 Nov 2015

The 5th annual SmartRail USA event took place last October in Charlotte, North Carolina. Attracting 400+ visitors across the two days, the congress led exhibition put innovative and new technology at the forefront of discussions on how to build the transportation system of the future. SmartRail USA presented a range of expert case studies, diverse panel discussions, interactive roundtables and networking opportunities to engage and bring together the transit community to share best practice and introduce innovative solutions to the national transport IT issues. Managing Directors such as Leanne Redden (Executive Director, RTA Chicago), Joseph C. Szabo (Executive Director, CMAP) and Keith T. Parker, (CEO, MARTA) shared their strategic insights for their transit agencies. While technical experts such as Dennis Story (Senior Manager, Communication & Control Systems, DART), Thomas Shaw (Manager, ATC Design and Construction, WMATA) and Richard Carter (Manager of Microwave, Norfolk Southern Railway) highlighted technical innovation. The SmartRail exhibitors also highlighted their smart transit innovation in the technical seminar room. Experts from companies such as Axinom, Alcatel Lucent, Lilee Systems, Nomad Digital, BAI Communications and CyberSecurity Analysis showcased their solutions and technology, complimenting the needs of the industry as highlighted in the congress. The annual SmartRail USA Innovation Awards were presented to winners Bombardier for Product of the Year and LA Metro for Project of the Year. Al Martinez, Director, Information Management at Los Angeles County Metropolitan Transportation Authority on winning the award: “We are excited to have received the Project of the Year Award from SmartRail USA. LA Metro is working hard to research new and innovative tools that will improve the customer experience as well as safety for the transit riders of Los Angeles. We believe implementing this new intelligence based surveillance system on our rail fleet will move us closer to this goal. We are grateful for recognizing LA Metro’s efforts with this award.”

Trilateral meeting among the vice presidents of Iran-Kazakhstan-Turkmenistan Railways

26 Nov 2015

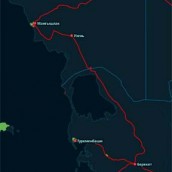

During numerous trilateral meeting among the railway authorities of Iran, Kazakhstan and Turkmenistan the existing obstacles were discussed. Fibally, a trilateral meeting among theDeputies of the said three railways was held last October in Tehran with an approach to provide facilities for more development of rail transportation among the three countries. There exists a considerable volume of consignment in Kazakhstan which must be carried to through the territory of the I.R. of Iran, the Persian Gulf States and other countries. Accordingly, these three took necessary measures for construction of Gorgan-Incheh Borun-Atrak-Berekat railway in their territory, i.e. around 120 km of the line is located in Kazakhstn, 700 km in Turkmenistan and 85 km in Iran.

(Photo: Svetlov Artem – Wikimedia Commons)

Eurostar E320 enters service

26 Nov 2015

The first of Eurostar’s 17 Siemens-built Velaro e320 trainsets began operating in limited commercial service on November 20, having been authorised for passenger operation through

the Channel Tunnel the previous day. According to Eurostar: “we received the final piece of safety authorization earlier than expected”, allowing the company to put the first train into

traffic on the 10.24 departure from London to Paris. The unit will operate ‘a small number of services’ on this route over the next few weeks in order to ‘fine-tune the onboard service’ ahead

of a formal launch in mid-December. The trains are expected to enter regular service before the end of this year, with all 10 of the first build ordered in 2009 due to be available by May

2016. On test for more than a year, the 320 km/h trainsets were formally authorized to operate in France by French safety authority EPSF on October 16. The final approval for use in

the Channel Tunnel was issued by the Intergovernmental Commission on November 19. As well as operating on existing routes, the e320s are also equipped to run into the Netherlands.

However, Eurostar has delayed the launch of its planned service to Amsterdam from December 2016 until early 2017. Styled by Pininfarina, the 16-car e320 with distributed traction equipment has three cars with premier seating at each end, flanking 10 standard class cars and two buffet-bar areas at the centre of the formation. Each trainset can carry up to 902 passengers.

(Source: http://www.railwaygazette.com – Photo: Siemens AG, Munich/Berlin)

First vertical structure at the Fresno River viaduct

26 Nov 2015

The California High-Speed Rail Authority (Authority) and its design-build contractor Tutor Perini/Zachry/Parsons (TPZP) advanced work on 16 vertical columns that will support the

Fresno River Viaduct. The viaduct is the first vertical structure being built as part of the California High-Speed Rail program. Significant construction work at this site began in June and

most recently, the construction team has been working to build the 16 columns that will support the approximately 1,600-foot length of the viaduct. The Fresno River Viaduct will span from

Raymond Road to Watson Street in Madera County, crossing over the Fresno River and State Route 145, parallel to the Burlington Northern Santa Fe tracks. The viaduct is part of Construction Package 1, the first 29-mile construction area that stretches from Avenue 17 in Madera County to East American Avenue in Fresno County. Approximately 75 people will work on completing this structure, including TPZP subcontractors Moore TwiningA ssociates, Becho, Inc., Landavazo Bros., Inc and Schwager Davis, Inc. with materials being supplied by Martinez Steel Corporation and Outback Materials.

Indian railways doubles cancellation charges

26 Nov 2015

The railways has some bittersweet news for passengers. While it doubled ticket cancellation charges, it reduced the deadline to cancel waitlisted and reservation against cancellation (RAC) tickets to half an hour prior to departure of the train. The changes, which were announced earlier, came to effect on Thursday. The railway has said the move is to make cancellations more convenient to passengers and end black marketing of tickets by touts. The passengers who cancel their tickets even 48 hours prior to departure will lose anywhere between Rs 120 to Rs 300 per ticket. This is against the earlier cancellation charges of Rs 60 to Rs 150 per ticket. “While clerkage levied for cancellation has been raised from Rs 30 to Rs 60 for any

reserved class, cancellation charges have gone up from Rs 120 to Rs 240 for first air conditioned executive class, Rs 100 to Rs 200 for second class air conditioned coaches, Rs 90 to Rs

180 for third class AC coaches and Rs 30 to Rs 60 for second class tickets”, stated the press release from the railways. Even clerkage charges for cancellation of unreserved tickets has gone

up from Rs 15 to Rs 30.

(Source: http://timesofindia.indiatimes.com –Photo by World 8115 – Wikimedia Commons)

Asian cities dominate ranking of the world’s biggest and busiest metros

26 Nov 2015

This is what emerges from a new report from UITP, the International Association of Public Transport. The report, “World Metro Figures”, is a comprehensive study on the current state of the world’s metro networks and highlights potential future developments. The report shows that in 2014, 156 cities around the world had a metro system in operation, nearly two thirds of which were in Asia and Europe. The world’s busiest metro network is the Tokyo metropolitan area, with almost 3.6bn passenger journeys per year, a 10% increase compared to 2012. Chinese metro systems have also enjoyed significant growth and Beijing (3.4bn, +39%) and Shanghai (2.8bn, +25%) are 2nd and 3rd respectively. Rounding out the top five are Seoul (2.6bn, +8%) and Moscow (2.4bn, -1%). Metros carry over 160m passengers per day (+7.9% compared to 2012), nearly half of which are in Asia. Asian cities are also on top when it comes to the world’s longest metro networks, with the Chinese cities of Shanghai and Beijing boasting 548km and 527km of lines respectively, while London rounds out the top three with 436km. In 2014 alone, more than 500km of new lines were added in cities around the world.

A new MoU between Italy and Congo

26 Nov 2015

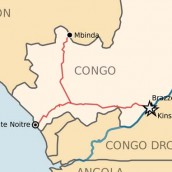

A new training and support agreement was signed by the Italian Ferrovie dello Stato (FS) and Chemin de Fer Congo-Ocean (CFCO), the main railway company of the Republic of Congo. The memorandum of Understanding was signed at Palazzo Chigi at the presence of the Italian Prime Minister Matteo Renzi, and the President of the Republic of Congo, Denis Sassou N’ Guesso. The agreement was signed by Michele Mario Elia, CEO of FS, and Jean-Francois Coutin, CEO of CFCO. The MoU aims to develop cooperation between the two rail groups, especially on topics related to training and technical assistance. The Congolese railway group is interested in training support for the maintenance of the network and the supply of rolling stock

for maintenance. The Italian FS Group will also offer its technical expertise, through Italferr, for the review of the National Transport Plan. Italferr is also monitoring the reconstruction project of the Kintelè district, in Brazzaville, for which Italy and Congo signed a Memorandum of Understanding in July 2014. The FS are also involved in the development of the new railway line between Pointe Noire and Brazzaville.

(Source: © 9Colonne)

Company Profile: ITT Interconnect Solutions

29 Sep 2015

ITT Interconnect Solutions (ICS), a division of ITT Corporation, manufactures highly engineered, customized electrical and data connectors for the energy, aerospace, transportation and industrial markets. Within ITT ICS, the brand dedicated to the rail sector is Veam. The brand was originally established in 1936 as a manufacturer of screw machined parts, and began producing connectors in 1953. Veam was acquired by Litton Industries in 1969, which was itself acquired by Northrop Grumman in 2001.

Veam was then acquired by ITT in 2003, and in 2007, ITT Cannon Italy & Veam merged into ITT Cannon Veam Italia. The brand

has always focused on understanding challenges unique to specific customers, and designing highly tailored connector solutions to meet those specified needs.

What is your mission?

First and foremost, our mission is to enable the safe and reliable mobility of people, goods and equipment. We do that by providing electrical interconnects that allow rail equipment – primarily rolling stock, its subassemblies and components – to operate effectively in harsh environments over long lifetimes. We have always made it a priority to offer our customers complete, globally leveraged customization based on their unique needs, working with unique mechanical, electrical and form factor requirements. From design to manufacturing and distribution, we take great pride in delivering highly tailored interconnects that are reliable, cost-effective and created from the ground up to address specific customer challenges.

What is your specialization?

Our core business at ITT Veam is designing and producing robust interconnects for the transportation and industrial markets – including high speed, freight and passenger rail applications, nuclear power plant control systems and a full range of heavy vehicles. Applications include bogie, inter-vehicle, coupler, data communication, internal car, and railway infrastructure connectors.

Our engineers have a reputation for designing interconnects that function under tough conditions of vibration and shock, and that provide long-lasting performance through exposure to snow, sleet, rain, hail and other harsh environmental stressors including corrosion and pressure. Our connectors play an integral role in the infrastructure and electrical control functions in current and next-generation railway systems, performing in on-and off-board applications and providing reliable connections for electrical and data signals. We engineer our solutions to withstand the harshest environments – especially undercar, coupler and inter-vehicle connections, which are often exposed to the elements over the course of years. We also offer our clients a range of value-added services including harnessing, cable assemblies, customized junction boxes and jumper cables.

Can you list and describe your brands?

We have two brands focused on the transportation and industrial markets – Veam and Cannon. While the majority of rail solutions fall under the Veam brand, some of our connectors for industrial applications and electric vehicles are also included in the Cannon portfolio. The Cannon brand, which celebrates its 100th anniversary this year, produces interconnects for aircraft – military and commercial – hospitals operating sophisticated automated equipment, heavy and off road vehicles, and film, TV and audio production equipment. Together, the brands cover a range of industries for ITT, including space, aviation, defense, handheld devices, industrial, transportation and medical. Our third brand, BIW Connector Systems, is focused on electrical connectors for the energy market, predominantly in upstream energy production. Veam and Cannon have a history of dedication to innovation in the rail market, and offer a broad range of electrical and optical interconnect solutions that support automotive markets, rail vehicles, engine diagnostics, brake controls, environmental conditioning, electromechanical, electrical, computer and entertainment systems.

Which are your foreign markets?

ITT Corporation is an American company headquartered in New York, but we are a company with a truly global footprint. ITT’s Veam brand has a regional manufacturing presence in Lainate, Italy, Shenzhen, China and Nogales, Mexico. These facilities along with our design, sales, and distribution facilities on all three continents, serve our growing North American and Asian markets, while supporting existing customers in Europe. The Lainate plant provides high quality and reliable products combined with local customer support to serve the European region and support the global market. As the rail market becomes more consolidated and global, the need to offer solutions applicable across all regions is intensifying. To offer just one example, Chinese rail car manufacturer China Railway Rolling Stock Corp and the U.S. state of Massachusetts recently announced that the Chinese firm would open an assembly plant to supply railcars for the Massachusetts Bay Transportation Authority. We are keeping our finger on the pulse of the global shift underway in this market, and have the infrastructure and capabilities in place to continue offering our customized solutions on a global scale.

Where are you working on at the moment?

We have large ongoing projects in Europe, North America and China, and work closely with rolling stock Original Equipment Manufacturers (OEMs) as well as Tier 1 suppliers to the rail industry to provide connectors that continually push the boundaries of performance, endurance and reduced environmental impact. Our highest performance connectors are for high-speed trains that travel up to 400 km per hour. In Europe, ITT Veam connectors serve 25 million passengers per year in multiple metropolitan and inter-European rail applications. Our connectors also support underground metro systems in the three mentioned regions. Working closely with industry technicians, we have developed ceramic heat-resistive inserts, Restriction of Hazardous Substances (RoHS) compliant corrosion-resistant conductive platings, flame retardant insular materials, connectors that integrate power, signal and data lines within a single unit, field configurable circular connectors, high temperature connectors, and shielded solutions for data transmission that bundle Ethernet, WTB, MVB and video lines in one connector.

A Collaboration with Alstom for the 2016 Summer Olympics in Brazil

Alstom asked ITT Veam to develop a custom connector to enable their regenerative power system, Ecopack, to effectively harness power generated by braking and store it in on-board batteries. Alstom was looking for a highly tailored rail solution offering high performance, safety and reliability in a very limited amount of space. They needed a connector that would enable energy generated during traction and braking to flow to the tram’s supercapacitors. Alstom asked ITT to engineer a high-performance, compact connector rugged enough to deal with tough conditions yet safe and easy to disconnect for servicing and maintenance. The result was the Veam Power Plate connector. This multi-pole interconnection system is suited for high power applications and can withstand harsh environments while delivering power dependably. Power Plate is critical to the success of Ecopack. By connecting the power equipment – which collects energy during breaking – with supercapacitors on the roof of the vehicle, Power Plate ensures that energy flows unimpeded to power the tram, and that the tram uses one third less energy than traditional systems. Power Plate features a double screw latching mechanism that provides a fast connect and disconnect capability, meets railway standards on smoke and fire protection, and saves space due to its unique receptacle and plug dimensions. The first of the 32 Alstom Citadis trains was delivered to Rio de Janeiro in June. And with Veam Power Plate having proved its effectiveness, Alstom has announced the regenerative power system will become a standard on all Alstom trains operating without catenary power.

Officially opened the Ashkelon – Beer Sheva line

28 Sep 2015

The Israeli prime minister Mr Benjamin Netanyahu, together with Israel’s transport minister Mr Israel Katz, and Israel Railways’ general manager Mr Boaz Zafrir, officially opened the 70km Ashkelon – Beer-Sheva line on September 17. Public services on the double-track line started two days later on September 19. Israel Railways is operating 25 trains per day in each direction, with two trains per hour during peak periods. The journey time is 50 minutes with trains calling at Shderot and Ashkelon, and from December at Ofakim. To stimulate traffic, the government has agreed to allow passengers from Shderot, Netivot, and Ofakim a 50% reduction on rail tickets to any destination in Israel.

The project

The railway line from Ashkelon southwards, including linking it up with the Lod – Na‘an – Be`er Sheva Line and construction of new stations at Sderot, Netivot and Ofakim. The project involved the construction of 3 road bridges, 18 railway bridges, 4 grade separations, 11 agricultural crossings, and 48 culverts; the numerous infrastructures disposed along the route were also to be attended to by means of protective shielding or relocation. The project was divided into two main sections: Ashkelon – Netivot, and Netivot – Be`er Sheva. The Ashkelon – Yad Mordechai portion of the Ashkelon – Netivot Section was laid in double track formation; the remainder as far as Netivot was constructed as a single track line with an infrastructure suitable for double tracks. The Netivot – Be`er Sheva Section was laid in single track formation with infrastructure elements ready for future track doubling.

Route length: 60 km.

Expected journey time: Approximately 47 min. from Ashkelon to Be`er Sheva.

Peak hour service frequency: 2 trains in each direction.

In the future—4 trains in each direction (73 trains per day).

Sources: http://www.railjournal.com – http://www.rail.co.il

Photo: by Highlighted rail lines and stations added by משתמש:בן-ציוןממ English labels added by Atefrat – Wikimedia Commons

12 more trains to boost capacity of North-South and East-West lines

28 Sep 2015

The Land Transport Authority (LTA) has awarded a contract worth approximately S$136.8 million to Kawasaki Heavy Industries, Ltd/CSR Qingdao Sifang Co. Ltd/Kawasaki Heavy Industries (Singapore) Pte. Ltd. Consortium for the purchase of 12 new six–car trains for the North-South and East-West Lines (NSEWL). These 12 trains are the final batch of the 57 new trains that will be put into service from 2016 to 2019. The first of these 12 trains will arrive in Singapore in early-2018, and will undergo testing at the NSEWL depots before they are put into service around the middle of 2019. These NSEWL trains will be the first trains to feature tip-up seats that will provide additional flexibility in seat configuration. The trains will also come with commuter-centric features such as three rows of straphangers and triplicated grab-poles for standing passengers. Commuters can also refer to the Dynamic Route Map Display located at the top of each door for their current location, route information and the side the train doors will open at the next station. Kawasaki Heavy Industries, Ltd. has been in the railway manufacturing industry for over a century. Besides supplying trains in the Japanese domestic market, Kawasaki’s existing overseas projects include metro trains for the New York City Transit Authority and the Washington Metropolitan Area Authority. In Singapore, Kawasaki has supplied most of the trains on the NSEWL. Its first delivery was for the inaugural fleet of 66 six-car trains in 1986, with additional fleets of 56 trains delivered in 1999, 2011 and 2013. CSR Qingdao Sifang Co. Ltd has a history of cooperation with Kawasaki dating back to 1985. Since then, the two companies have worked on several joint contracts of linear motor MRT trains for Guangzhou Metro Line 4 and 5 and of high-speed trains for the Ministry of Railways of China. The Consortium is currently in progress of delivering 91 trains for the Thomson – East Coast Line.

More New Trains on Rail Network

From the start of this year to 2019, 99 more trains will be added to the NSEWL, North East Line (NEL) and Circle Line (CCL), increasing the overall train fleet size by close to 50%. This includes the 57 new trains for the NSEWL which will enter service from 2016. For the CCL, 12 new trains would have joined the CCL’s existing fleet of 40 trains by the end of 2015[2]; while four new trains would also have been added to the North East Line’s (NEL) fleet of 25 trains. By the end of 2016, all the 42 new trains for the CCL and NEL would be fully deployed

PKP CARGO develops a modern fleet for Europe

28 Sep 2015

PKP CARGO shall purchase 15 multi-system locomotives from the Siemens Group. These locomotives are intended for PKP CARGO trains in Poland and six other states of the European Union. Siemens will supply the locomotives to PKP CARGO starting from January 2016, with the last one to be delivered in 2017. The contract signed between the parties contains the option of fixed-price purchase of another five engines, which will be decided by PKP CARGO by the end of 2017. The multi-system locomotives enable smooth freight between the countries with different power systems. The contract was signed in the course of the International Railway Fair held in Gdansk. The contract value amounts to net EUR 75 million (app. PLN 315 million). “This is our greatest investment in rolling stock in long-time perspective and one of the largest tender procedures of such type in this part of Europe. After the acquisition of the Czech AWT we made another step towards building the international position of PKP CARGO and strengthening of our presence in the neighbouring countries. The multi-system locomotives are a cutting edge rolling stock making our offer of international freight even more competitive for the Polish and foreign Clients” –says Chief Executive Officer of PKP CARGO Adam Purwin. The multi-system locomotive is adapted for operation under the different power systems without the need to stop the train. It enables seamless operation of transborder transport in the countries with different rail network voltages. This solution enables freight from Germany to Hungary via Poland, Czech and Slovakia with a single locomotive and a single carrier.

The first Vectrons in January 2016

The first three from 15 new machines will be delivered to the rolling stock park at the end of January 2016, whereas the three subsequent ones a month later. The last engines (approved for seven EU Member States) will be supplied at the end of 1H 2017.To this moment, PKP CARGO had only one multi-system locomotive and the remaining ones were leased (operating lease). Such solution enabled rapid and flexible responding to the fluctuating freight conditions and allowed for obtaining the safety certificates abroad. At present, PKP CARGO implemented the stabilized level of multi-system locomotives use. In such conditions, purchase is the most favourable option, enabling more effective price competition with the foreign carriers. PKP CARGO is the largest rail freight carrier in Poland, with market share exceeding 56% in terms of transport performance (1H 2015). Rail freight of imported or exported goods generates more than 40% of transport performance of PKP CARGO. Apart from rail freight, the PKP CARGO Group acts also as a forwarder and terminals and sidings operator. Its other activities cover also repairs and maintenance of the rolling stock.

Winners announced for SmartRail USA Innovation Awards 2015

28 Sep 2015

The votes have all been counted and the winners of the inaugural SmartRail USA Innovation Awards 2015 have been confirmed. After a three month process this nationwide search for the most innovative new products and solutions for the transit (rail, metro and bus) industry in North America we finally have the winners. Both of whom will receive their awards at SmartRail USA Congress & Expo in Charlotte on October 28th. So who has won what? And who came in as runners up and highly commended after thepanel of judges voted?

Bombardier took the Product of the Year title with their YardSafe state-of-the-art engineered safety solution which provides improved location awareness for workers in rail yards and maintenance facilities. Speaking on the confirmation of their win Mark Willer, Product Manager, Technology Systems at Bombardier: “We are extremely pleased to have been selected by the SmartRail judging panel as the winning entry for Product of The Year for 2015. Bombardier’s Technology Solutions team is dedicated to developing and delivering systems that add real value and improve safety in the rail transit industry. We believe this award is a reflection of our team’s vision for the innovative application of technology and our commitment to achieving these goals. We would also like to recognize our colleagues in Bombardier that supported UP Express. Our team of Train Operating Crews, Guest Service Representatives and Maintenance teams along with their related management teams are thrilled to be a part of and to deliver such a world class link between Pearson Airport and Toronto’s downtown core”.

The Project of the Year title was secured by Los Angeles County Metropolitan Authority (LA Metro) with their new intelligence based surveillance system being implemented as part of a 30 year rail transit expansion. Al Martinez, Director, Information Management at Los Angeles County Metropolitan Transportation Authority on winning the award: “We are excited to receive the Project of the Year Award from SmartRail USA. LA Metro is working hard to research new and innovative tools that will improve the customer experience as well as safety for the transit riders of Los Angeles. We believe implementing this new intelligence based surveillance system on our rail fleet will move us closer to this goal. We are grateful for recognizing LA Metro’s efforts with this award”.

One of the panel of judges Jim Allison, Planning Manager, Capitol Corridor Joint Powers Authority (CCJPA) on the final voting said: “It’s a testament to the industry that there were so many high quality entrants across a wide variety of diversity of applications. It was not easy to pick the most transformational projects”. Whilst another judge, Paul C Worley, Rail Division Director, North Carolina Department of Transportation added: “I enjoyed being a part of Smart Rail’s competition for new technology in the rail industry. It was very interesting and rewarding to review the various new approaches to making rail operations safer and more efficient”. The winners will receive their awards at a ceremony at SmartRail USA Congress and Expo in Charlotte, North Carolina 28-29th October 2015. SmartRail USA is the only show dedicated to driving innovation in passenger rail in North America and is free to attend.

Award Details

Product of the Year identifies the best and most innovative products in the rail industry. Hardware or software, it can be a new product, an update of an existing solution or an improved way of utilizing current technology that will improve our industry. The focus can be large or small but the product and the improvement it makes is the important factor. Open to entrants from solution providers and individuals.

Winner: Bombardier (YardSafe™ – Innovation in improving Safety and Effectiveness within Rail Yards)

Runner up: Divvali LED (LED Locomotive Lamps)

Highly commended: Radwin (FiberinMotion Train-to-Ground Solution); Moovit (Your City, Your Local Transit App); One Bus Away (The Open Source platform for Real Time Transit Info)

Project of the Year recognizes new developments and ways of thinking in improving and increasing efficiency in rail project delivery and management. With a particular focus on projects that have helped deliver a safer, more reliable transit network, increased capacity, boosted ridership or improved passenger experience. We welcome entrants from transit agencies as well as solutions providers.

Winner: LA Metro (Metro Rail Intelligence Based Surveillance System)

Runner up: Amtrak (Next generation wireless communications project)

Highly commended: Up Express (An Integrated Transit Solution for Toronto)

The Judging Panel: Robert Stewart, Chairman, National Association of Railroad Passengers (NARP); Paul C Worley, Rail Division Director, North Carolina Department of Transportation; Jim Allison, Planning Manager, Capitol Corridor Joint Powers Authority (CCJPA); Alan F. Tilles, Attorney, Shulman Rogers; Dr. Kenneth Gilbert, Professor Emeritus, University of Tennessee; Luke Upton, Editor, SmartRail World

Hokkaido Shinkansen Line will run from March 26

28 Sep 2015

A long-awaited bullet train service that will link Hokkaido with Tokyo will open on March 26, railway operators have confirmed. Hokkaido Railway Co. and East Japan Railway Co. (JR East) will provide 13 round-trip runs per day on the Hokkaido Shinkansen Line. “This is an unprecedented project for the country, running through snowy areas and through the Seikan Tunnel (between Honshu and Hokkaido) as well as a section shared with cargo trains”- JR Hokkaido President Osamu Shimada said at a news conference at the railway’s headquarters in Sapporo. “We will put full efforts into starting the operation safely” Shimada added, noting that railway operators hope the passenger influx will benefit all of Hokkaido. Of the 13 runs, 10 will employ Hayabusa trains connecting Shin-Hakodate-Hokuto Station in southern Hokkaido and Tokyo. The fastest service will cover the distance in four hours and 10 minutes. One service will be covered by a Hayabusa train connecting Shin-Hakodate-Hokuto Station with Sendai, while Hayate trains will be employed for the remaining two services linking Shin-Hakodate-Hokuto Station with Shin-Aomori Station in Aomori Prefecture, and Morioka in Iwate Prefecture.

Source: http://www.japantimes.co.jp

Photo by Toshinori baba -Wikimedia Commons

Tanger high speed train depot inaugurated

28 Sep 2015

The rolling stock depot in Tanger which will maintain and service the country’s fleet of high speed trains was officially inaugurated by King Mohammed VI and French President François Hollande on September 20, at a ceremony attended by ONCF Director-General Mohamed Rabie Khlie and SNCF President Guillaume Pepy. Two of the 14 Alstom-built double-deck trainsets have already been delivered to the port of Tanger-Med and are now undergoing static commissioning before the start of test running. The two railways have also formally established the joint venture company which will run the depot under a 15-year contract valued at €175m. Launched on September 15, Société Marocaine de Maintenance des Rames à Grande Vitesse is owned 60% by ONCF and 40% by the French national operator. According to SNCF, the new depot and maintenance regime will be derived from that used in France. Under an inter-government protocol signed in October 2007, the two railways have been co-operating in a ‘partnership of equals’ to support the development of the Moroccan high speed line. A technical co-operation team of around 30 people has been working on the project since 2009. SNCF staff will also support the early phase of operations, ‘building on more than 30 years of experience’ since the start of high speed services in France. The two partners have jointly established a railway engineering and operations training centre in Rabat. Although its new buildings are not expected to be ready until next year, the Institute de Formation Ferroviaire began work at the end of March 2015. With 30 lecturers drawn from both railways, it has already provided more than 5 000 days of training to around 1 700 students. By the end of this year, more than 2.200 ONCF and 1.100 SNCF trainees are expected to have passed through the facilities. As well as training employees of the parent railways, IFF will also make its courses available to other railways in Africa and the MENA region.

TMONET Joins OSPT Alliance to Expand its Mobile Pa yments Service Beyond Korea

28 Sep 2015

OSPT™ Alliance, the international association which provides an open standard for secure transit fare collection solutions, has welcomed TMONET, a mobile payment service and solution provider based in South Korea, as a Full Member. TMONET operates Mobile T-Money, the mobile application of the T-Money payment card launched by its partner, Korea Smart Card Co. (KSCC) in 2004. The service, which has been adopted in South Korea and New Zealand, allows users to make transactions for public transport fare collection and retail via a mobile phone. TMONET holds 90% of the mobile payment market share in Korea, with a service that has been adopted by 3.500.000 users across 45.000 bus and subway gates and 60.000 retail outlets. TMONET will integrate OSPT Alliance’s CIPURSE™ open standard – which offers an advanced foundation for developing highly secure, interoperable and flexible applications – into its Mobile T-Money solution. The company is evaluating opportunities to improve and expand its service, including the development of a cross-border mobile solution for transport ticketing. Seonku Lee, Vice President of TMONET, comments: “To maintain our position as a market leader in mobile payments it is important to constantly assess how our service can be improved and future-proofed. Security, usability and the enablement of seamless multi-application services are key factors that will be supported by integrating CIPURSE. We look forward to taking an active role in OSPT Alliance’s working groups and supporting the evolution of CIPURSE, both for the benefit of our Mobile T-Money solution – primarily within transit – and to facilitate its growth as a globally adopted standard. Ultimately, our aim is to develop a service that will enable cross-border travel via a single mobile device”. OSPT Alliance’s Executive Director, Laurent Cremer (in the picture) concludes: “More and more contactless applications, such as transport ticketing, payment and loyalty will be adapted to mobile devices over the coming years. To meet market requirements for cross border services, a secure, open, flexible and standardized foundation such as CIPURSE is imperative. I am pleased to see the standard gain traction in the mobile payments market, and excited to welcome TMONET, a company with significant market presence and expertise. I look with particular interest to its contributions to our global Working Groups and CIPURSE Mobile Sub-Working Group”.

CAF presents first passenger train to Saudi Railway Company

28 Sep 2015

The first of six passenger trains being built by CAF was handed over by the company’s CEO Mr Andres Arizlorret to the chairman of Saudi Railway Company (SAR) Dr Saad A Al Qadhi and SAR’s CEO Dr Rumaih Al-Rumaih at the new station in Riyadh. The train had completed its first test run on part of the North-South Railway between Nariyah and Riyadh, a distance of 1130km. CAF is supplying four day trains and two overnight trains under a contract worth in excess of €400m. Each 280m-long day train comprises a diesel power car at each end and nine intermediate coaches, while the night trains will have a similar formation but with 13 intermediate coaches. The day trains will be able to seat 444 passengers. Testing and commissioning of fleet is expected to take 10 months, and each train must complete 10.000 km of trouble-free operation before it can enter service. SAR plans to introduce its first passenger services during the second half of 2016. SAR will operate the day trains between Riyadh, Buraydah and Ha’il, while the night trains will run from Riyadh via Hail to Jawf and Qurayyat near the Jordanian border. Studies will start shortly into a rail link between SAR’s new station in Riyadh and the station owned by Saudi Railway Organisation (SRO) to enable the operation of through services between SAR’s North-South Railway and SRO’s main line to Dammam.

Source: http://www.railjournal.com

Addis Ababa’s first light railway comes online

28 Sep 2015

Addis Ababa’s $475-million light railway project became operational last 20th September following a colorful inauguration ceremony. According to Getachew Betru, CEO of the Ethiopian Railway Corporation, the new railway is capable of transporting up to 60,000 people each day. Speaking to Anadolu Agency during the maiden trip, Getachew said the railway – built by the Chinese Railway Engineering Corporation (CREC) – stretched some 35 kilometers across the eastern, western and northern parts of the city, which hosts the headquarters of both the African Union and the Economic Commission for Africa. On Sunday, Ethiopian Transport Minister Workineh Gebeyehu and CREC representative Zhang Zongyan both cut the ribbon marking the railway’s formal inauguration. According to Workineh, the railway offers a cheaper, faster and safer mode of transport for residents of the capital, with minimum and maximum fares ranging between two and six birr (from about $0.10 to $0.30).Workineh noted, however, that revenues collected from passenger fares would not be enough to cover the total cost of construction. “It’s hugely subsidized” he said, pointing out that the Ethiopian government planned to spend up to $1.5 billion on subsidies for the railway’s operations. The part of the project that became operational accounts for half of the railway’s total length. The remainder will become operational over the next two months, according to rail officials. Asked about the city’s erratic power supply, Workineh said this had been addressed by providing the railway with its own dedicated power source. Peter Olaseni Akinwumni, rail project manager for the Lagos Metropolitan Area Transport Authority, who also spoke to Anadolu Agency during the maiden commute, described the new railway as “a remarkable achievement”. “Not only Ethiopia, but all of Africa needs such a railway network, which is cheaper and accommodates many people at once – the way other modes of transport cannot,” he said.

Source: http://www.aa.com.tr

Photo: by Turtlewong – Wikimedia Common

Metropolis for Kochi: design unveiled for the first time

28 Sep 2015

The design of the new Kochi Metropolis trainset, made by Alstom, was unveiled the 7th September by Kochi Metro Rail Limited (KMRL) to Kochi residents. Oommen Chandy, Hon’ble Chief Minister of Kerela, Elias George, KMRL Managing Director, and Bharat Salhotra, Managing Director of Alstom Transport India among others attended the event. The new metro will run on the Kochi’s new fully elevated metro rail network. Alstom – which was awarded the supply of 25 Metropolis trainsets in 2014 and 2 othersduring the course of 2015 – is the main supplier of the city’s new metro network. The Kochi metro was designed by Alstom’s Design&Styling department in Saint-Ouen in collaboration with the operator KMRL and TATA Elxsito enhance passenger experience, reflect KMRL’s identity and blend seamlessly into the city.The train is composed of 3 cars and is about 65 meters-long. It has an open gangway allowing passengers to walk from one end of the train to the other. The interior provides a feeling of serenity and security with sections marked in two bright, harmonious colors: green turquoise and lemon used for the seats and the handles. The metro train comprises 136 seats per car in a longitudinal seating arrangement optimizing transport capacity (975 passengers per car) and facilitating passenger boarding. The seats are made of a polyester composite, making them particularly easy to clean and maintain. For the comfort of elderly passengers or pregnant women, priority seats are filled with cushions. Persons with reduced mobility and wheelchair users will be able to use dedicated areas in the metro car while commuting. The front end of the train is made of polyester. Mostly green turquoise in color, it perfectly reflects KMRL’s new image, reinforced by the distinctive shape of its curved windshield. Representing an iconic symbol of India, the front LED lights are in the shape of elephant’s tusks. As the metro runs on a viaduct, the lights will illuminate the city at night. The side of the train is made of stainless steel. The train panels are made with aluminum and composites as well as anti-graffiti protection. The metro train features four external sliding doors per side making passenger traffic much smoother. Xavier Allard, Director Design & Styling, Alstom Transport said: “The design of the Kochi metro has set a new benchmark in urban mobility in India with its aesthetically-pleasing and stylish designs and technological innovations promoting greener urban transportation in the country. The metro for Kochi supports KMRL’s efforts to provide a comfortable, attractive and reliable service to Kochi residents and illustrates one of Alstom’s key strategies to enhance passenger experience”.

Travel green with public transport

28 Sep 2015

UITP (the International Association of Public Transport) is supporting the 2015 Mobility Week with a campaign aiming to highlight the vital role that public transport plays across the globe, transporting millions of people on a daily basis. In a world in which over 1,000 cities of more than 500,000 citizens are facing major mobility problems, UITP encouraged its members – and other transport stakeholders – around the world to join together in celebrating Mobility Week (16-22 September) to underline the crucial role played by public transport in keeping cities moving. In 2005, 47% of the daily trips worldwide were still made in private motorized vehicles, creating both pollution and congestion, degrading air quality and holding back economic growth. If significant action is not taken, energy use and greenhouse gas emissions are predicted to rise by nearly 30% by 2025 compared to 2005, primarily caused by a surge in the global stock of private vehicles. Encouraging a significant modal shift to public transport, as per UITP’s strategy of doubling the modal share of public transport by 2025, would play a major role in climate mitigation, making cities better places to live and work. “With more and more people living in cities across the globe, demand for urban mobility is rising, especially in developing countries,” said Alain Flausch, UITP Secretary General. “UITP’s campaign aims to highlight the vital role that public transport plays in both climate mitigation and sustainable growth”.

UITP and ECF together for more sustainable and active mobility

Another step towards greener and safer cities is the meeting between UITP and ECF (European Cyclists’ Federation) last 14th September to sign the very first Memorandum of Understanding between the two structures. The agreement will see the two work more closely on policy initiatives in order to strengthen the voice of sustainable urban transport. ECF and UITP have worked together for several years, both members of the SLoCaT Partnership (Sustainable Low Carbon Transport) and ECF being part of the UITP Combined Mobility Platform, and decided to take the relationship a step further. Both organizations will work closer together to achieve more sustainable and active mobility in Europe and support each other’s missions to ‘Double Cycling’ and ‘Double Public Transport’. For Europe, this would mean 15% of all trips to be cycled and doubling the modal share of public transport by 2025, which would result in more liveable and performing cities, contribute to green growth, and fight against climate change. Both parties see the benefits of an enhanced partnership to establish a stronger lobby position when talking to the European Institutions or the United Nations. Bernhard Ensink, Secretary General ECF said: “It is an important year to work together on the COP 21 and create impact in the process of the Sustainable Development Goals”. “Signing this Memorandum to kick off European Mobility Week 2015 marks a timely occasion to further strengthen ties between the public transport and cycling communities and unite to call for more sustainable mobility choices worldwide”- said UITP Secretary General Alain Flausch. The signature starts a more intensive collaboration process for the development of policy messages on economic benefits of sustainable mobility, public health, transport policy, and urban mobility data collection.

More information available on: http://www.uitp.org/mobilityweek

Trieste hosts the first Forum on Italo-Balkan relations

28 Sep 2015

The Balkans are one of the European regions with the most potential for development in the near future. The upgrading of the railway network and its complete integration in the TEN-T European Corridors is one of the most important drivers for the growth of the economies of the countries in that area. The strategies for the development of the railway infrastructures between Italy and the Balkans were the focus of a specialized Forum on 17 and 18 September, organized in Trieste by CIFI (Collegio degli Ingegneri Ferroviari Italiani – College of Italian Railway Engineers) with the cooperation of Gruppo Ferrovie dello Stato Italiane, Assifer (the association of Italian railway industries) and Aniaf (industrial enterprises specialized in railway superstructures). And of course Trieste was not chosen by chance: the capital of the Friuli Venezia Giulia Region is Italy’s natural port towards the Balkans, one of the main ports of the Adriatic Sea and it is involved in important railway projects. In addition to the CEO of FSI, Michele Mario Elia, the CEO of RFI, Maurizio Gentile, and that of Italferr, Matteo Triglia, and RFI engineers Enzo Marzilli, Donato Carillo and Giovanni Costa, the Forum was also attended by the representatives of Railway Administration Boards of Slovenia, Macedonia, Bulgaria, Albania and Montenegro. In the first part of the Forum, Gruppo FSI and the Railway Administration Boards of the guest countries illustrated their development programmes. This was followed by a second part dedicated to Italian industrial enterprises belonging to the sector which described their activities with particular attention to the possible need for the renewal and upgrading of the Balkan networks. The talk given by the CEO of Gruppo FSI, Michele Mario Elia, was of particular interest; he detailed the investments already in course and those planned for the future which are, directly or indirectly, functional to the development of railway relations with the Balkans. Elia reminded his listeners that the Adriatic-Ionian area includes a territory with a population totaling to approx. 60 million inhabitants, with a GDP of around 1000 billion euros, 600 of which are produced in the Italian regions overlooking these two seas. Integration between the two shores is facilitated by the railway infrastructure network, maritime links, intermodal hubs and port terminals. The commitment of Gruppo FSI is, therefore, chiefly focused on the technological upgrading of the link between Trieste and Venice, with an overall investment estimated to be around 250 million euros, and on that between Trieste and Divača, in Slovenia for which feasibility studies are currently underway, but also on the upgrading of the railway infrastructures that serve the Port of Trieste, for which 50 million euros have been earmarked. Moreover, FSI has commenced an upgrade on the entire Adriatic railway line that serves the ports overlooking the Balkans, from Ravenna, to Ancona, Brindisi and Taranto, with an increase in capacity and loading gauge. But Gruppo FSI has been operating in many countries in the Balkans for sometimes now, through its own engineering company, Italferr, and its certification company, Italcertifer. Italferr is involved, in Serbia and Montenegro, on studies for the upgrading of the goods line from Belgrade to the port of Bar, and it is working on the National Transport Plan. Feasibility studies have also commenced in Croatia for the upgrading of Corridor X, and in Albania for the new passenger station of the capital city, while in Bosnia a review of the local railway regulations is underway. Meanwhile, Italcertifer is working in Serbia, Greece and Bulgaria for the certification of traffic control systems and entire new railway lines.

by Franco Tanel

Port link opened under non-government railway policy

22 Jul 2015